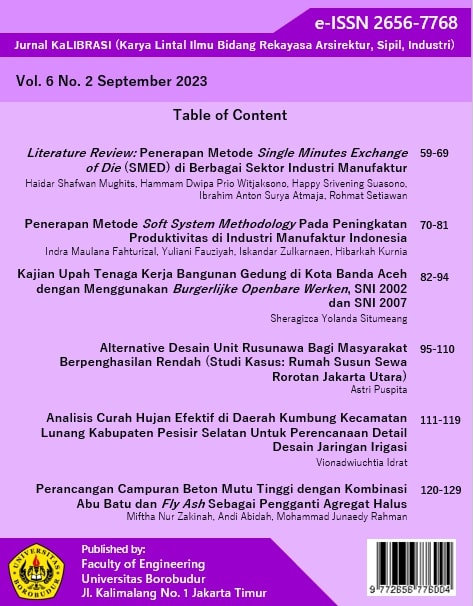

Penerapan Metode Soft System Methodology Pada Peningkatan Produktivitas di Industri Manufaktur Indonesia

DOI:

https://doi.org/10.37721/kalibrasi.v6i2.1190Keywords:

Produktivitas, Metodologi Sistem Lunak, Pemodelan, Industri Manufaktur, Tidak Bernilai TambahAbstract

Seiringnya dengan perkembangan bisnis di Indonesia, beberapa industri manufaktur di Indonesia mengantisipasinya dengan adanya kreatiftas dan inovasi. Setiap perusahaan dituntut untuk menerapkan beberapa pemodelan dalam melakukan perbaikan sistem. Permasalahan yang sering terjadi diantaranya: beberapa industri manufaktur di Indonesia mengantisipasinya dengan adanya kreatiftas dan inovasi. Masalah yang sering terjadi di perusahaan adalah waktu henti pada setiap line produk dan mengakibatkan target produksi tidak tercapai, sehingga mempengaruhi pengiriman produk ke pelanggan. Penelitian ini bertujuan untuk membuat sistem pemodelan yang diharapkan dapat meningkatkan produktifitas kinerja, sehingga target produksi dapat tercapai dan pengiriman produk ke pelanggan tidak terganggu. Penelitian ini menggunakan metode Soft System Methodology (SSM) dalam menganalisa dan melakukan perbaikan. Hasil dalam penelitian ini berupa sistem pemodelan dalam perbaikan dengan 6 tahapan atau langkah perbaikan diantaranya identifikasi masalah, causal loop diagram ketidakefektifan mesin, rich picture ketidakefektifan mesin, root definitions, model konseptual peningkatan produktivitas perusahaan, dan proses debating.References

Aisyah, S., Jaqin, C., & Purba, H. H. (2019). Identification Of Lean, Agile, Resilient, And Green (Larg) Practices On Agro Industry Indonesia. 17(Icoemis), 62–69. https://doi.org/10.2991/icoemis-19.2019.10

Amrina, U., & Elisa, N. (2019). Application Of Sustainable Productivity Management In Footwear Companies By Green Manufacturing Approach. Sainstech: Jurnal Penelitian Dan Pengkajian Sains Dan Teknologi, 29(2), 37–42. https://doi.org/10.37277/stch.v29i2.336

Arifin, D. (2018). Analisis Perbaikan Waktu Setup Dengan Menggunakan Metode SMED Untuk Meningkatkan Produktivitas PT. Trimitra Chitra Hasta. Jurnal KaLIBRASI - Karya Lintas Ilmu Bidang Rekayasa Arsitektur, Sipil, Industri., 1(1), 1–14. https://doi.org/10.37721/kalibrasi.v8i0.313

Ats-Tsauri, M. I., Wilarnugroho, B., & Purba, H. H. (2022). A conceptual model for energy management in the steel industry: A Soft System Methodology (SSM) approach. Sinergi, 26(3), 319. https://doi.org/10.22441/sinergi.2022.3.007

Chiarini, A., Baccarani, C., & Mascherpa, V. (2018). Lean production, Toyota Production System and Kaizen philosophy: A conceptual analysis from the perspective of Zen Buddhism. TQM Journal, 30(4), 425–438. https://doi.org/10.1108/TQM-12-2017-0178

Fauzi, A., Galang, R., Kurnia, H., Egga, D., & Usman, M. (2023). Penggunaan Non-Metallic Material di Berbagai Industri Manufaktur Indonesia Secara Tinjauan Literatur Sistematis. Jurnal Kalibrasi, 6(1), 13–21. https://doi.org/10.37721/kalibrasi.v6i1.1123 1.

Gomes, M. N., Baptista, A. J., Guedes, A. P., Ribeiro, I., Lourenço, E. J., & Peças, P. (2017). Multi-layer stream mapping: Application to an injection moulding production system. Smart Innovation, Systems and Technologies, 68(April), 193–202. https://doi.org/10.1007/978-3-319-57078-5_19

Irpana, R., Herindiyati, H., & Novitawaty, M. (2023). Perancangan Pusat Konvensi Dengan Pendekatan Arsitektur Dekonstruksi di Jakarta. Jurnal KaLIBRASI - Karya Lintas Ilmu Bidang Rekayasa Arsitektur, Sipil, Industri., 6(1), 30–38. https://doi.org/10.37721/kalibrasi.v6i1.1144 1.

Kurnia, H., Jaqin, C., & Manurung, H. (2022). Implementation of the DMAIC Approach for Quality Improvement at the Elastic Tape Industry. J@ti Undip: Jurnal Teknik Industri, 17(1), 40–51. https://doi.org/10.14710/jati.17.1.40-51

Kurnia, H., Jaqin, C., & Purba, H. H. (2022). Quality improvement with PDCA approach and design of experiment method in single socks industry in Indonesia. International Conference on Informatics, Technology, and Engineering 2021 (InCITE 2021), 2470(January), 1–12. https://doi.org/10.1063/5.0080179

Kurnia, H., Jaqin, C., Purba, H. H., & Setiawan, I. (2021). Implementation of Six Sigma in the DMAIC Approach for Quality Improvement in the Knitting Socks Industry. Tekstilvemuhendis, 28(124), 269–278. https://doi.org/10.7216/1300759920212812403

Kurnia, H., Riandani, A. P., & Aprianto, T. (2023). Application of the Total Productive Maintenance to Increase the Overall Value of Equipment Effectiveness on Ventilator Machines. Jurnal Optimasi Sistem Industri, 1(22), 52–60. https://doi.org/10.25077/josi.v22.n1.p52-60.2023

Mitra Debnath, R. (2019). Enhancing customer satisfaction using Kaizen: a case study of Imperial Tobacco Company (ITC). Journal of Advances in Management Research, 16(3), 277–293. https://doi.org/10.1108/JAMR-01-2018-0009/FULL/XML

Mulyana, A., & Hasibuan, S. (2017). Implementasi Single Minute Exchange of Dies (Smed) Untuk Optimasi Waktu Changeover Model Pada Produksi Panel Telekomunikasi. Sinergi, 21(2), 107. https://doi.org/10.22441/sinergi.2017.2.005

Nakajima, S. (1989). TPM development program: implementing total productive maintenance. Productivity press.

Patil, B. B., Badiger, A. S., & Mishrikoti, A. H. (2018). A Study on Productivity Improvement through Application of Total Productive Maintenance in Indian Industries-A Literature Review. IOSR Journal of Mechanical and Civil Engineering, 15(3), 13–23. https://doi.org/10.9790/1684-1503041323

Rahman, A., & Perdana, S. (2019). Analisis Produktivitas Mesin Percetakan Perfect Binding Dengan Metode OEE Dan FMEA. Jurnal Ilmiah Teknik Industri, 7(1), 34–42. https://doi.org/10.24912/jitiuntar.v7i1.5034

Roziko, H., Ardiansyah, Barnas, E., & Silviati. (2021). Analisis Produktivitas Tenaga Kerja pada Pekerjaan Struktur Rangka Atap Baja Ringan (Menggunakan Studi Kasus Rangka Atap Type Pelana dan Limasan Dengan Masing-Masing 5 Lokasi Proyek Berbeda). Kalibrasi (Karya Lintas Ilmu Bidang Rekayasa Arsitektur, Sipil, Industri), 4(2), 60–82. https://doi.org/10.37721/kalibrasi.v4i2.889

Setiawan, B., Setiawan, I., Kurnia, H., & Wahid, M. (2022). Implementation of the Value Stream Mapping Method in the Industry: A Systematic Literature Review. Journal of Industrial & Quality Engineering, 12(December), 103–116. https://doi.org/10.34010/iqe.v10i2.5989

Setiawan, I. (2021). Integration of Total Productive Maintenance and Industry 4.0 to increase the productivity of NC Bore machines in the Musical Instrument Industry. Proceedings of the 11th Annual International Conference on Industrial Engineering and Operations Management Singapore, 4701–4711.

Setiawan, I., & Setiawan, S. (2020). Defect reduction of roof panel part in the export delivery process using the DMAIC method: a case study. Jurnal Sistem Dan Manajemen Industri, 4(2), 108–116. https://doi.org/10.30656/jsmi.v4i2.2775

Setiawan, S. (2021). A Systematic Literature Review of Total Productive Maintenance On Industries. Performa: Media Ilmiah Teknik Industri, 20(2), 97. https://doi.org/10.20961/performa.20.2.50087

Sjarifudin, D., & Kurnia, H. (2022). The PDCA Approach with Seven Quality Tools for Quality Improvement Men ’ s Formal Jackets in Indonesia Garment Industry. Jurnal Sistem Teknik Industri (JSTI), 24(2), 159–176. https://doi.org/10.32734/jsti.v24i2.7711

Sjarifudin, D., Kurnia, H., Purba, H. H., & Jaqin, C. (2022). Implementation of the six sigma approach for increasing the quality of formal men ’ s jackets in the garment industry. Jurnal Sistem Dan Manajemen Industri, 6(1), 33–44. https://doi.org/10.30656/jsmi.v6i1.4359

Sudarni, A. A. C., & Wantira, A. D. (2022). Pemodelan Persamaan Struktural Variabel Budaya Keselamatan Pada Area Produksi Industri Baja. Jurnal Ilmiah Teknik Industri, 10(2), 151–160. https://doi.org/10.24912/jitiuntar.v10i2.16664

Suhardoyo. (2018). Analisis Implementasi Model Manajemen Kinerja Karyawan Pada Industri Manufacture Garment (Studi Kasus : PT. Tae Young Indah). Cakrawala - Jurnal Humaniora Bina Sarana Informatika. https://doi.org/10.31294/JC.V18I2.4221

Sukma, D. I., Prabowo, H. A., Setiawan, I., Kurnia, H., & Maulana, I. (2022). Implementation of Total Productive Maintenance to Improve Overall Equipment Effectiveness of Linear Accelerator Synergy Platform Cancer Therapy. International Journal of Engineering, 35(7), 1246–1256. https://doi.org/10.5829/ije.2022.35.07a.04

Wijaya, E. O., Atikno, W., Setiawan, I., Susanto, R., & Kurnia, H. (2022). Analysis of BTA16 CNC Machine Performance Improvement with Total Productive Maintenance Approach. IJIEM - Indonesian Journal of Industrial Engineering and Management, 3(3), 200. https://doi.org/10.22441/ijiem.v3i3.15770

Wiyatno, T. N., & Kurnia, H. (2022). Increasing Overall Equipment Effectiveness in the Computer Numerical Control Lathe Machines Using the Total Productive Maintenance Approach. Jurnal Optimasi Sistem Industri, 15(2), 284–292. https://doi.org/10.31315/opsi.v15i1.7284

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Jurnal KaLIBRASI - Karya Lintas Ilmu Bidang Rekayasa Arsitektur, Sipil, Industri

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.